Metrology and testing services

Professional measurement testing and calibration services to ensure measurement accuracy and reliability.

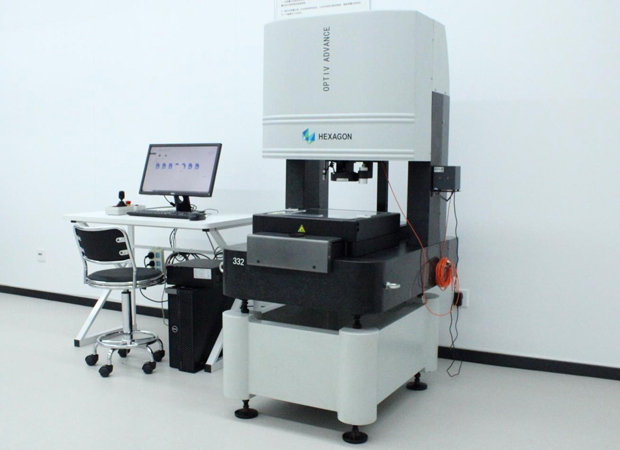

High-precision three-coordinate

Three-dimensional key dimension inspection

- Three-dimensional dimensions of bearing-related components (such as base parts, finished parts), including inner and outer diameters, curvature radius of raceways, and rib height

Spatial form and position tolerance inspection

- Spatial geometric tolerances such as coaxiality, circular runout, and flatness

Verification of conformity of measurement values

- Compare the inspection results with the design drawings to verify whether the dimensional deviations are compliant

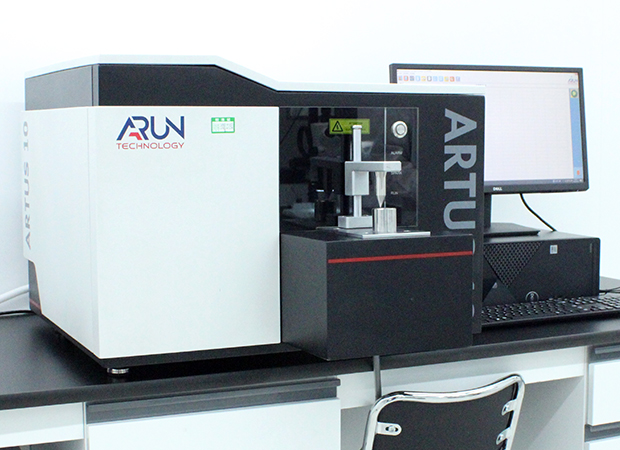

High-precision automatic length measuring instrument

One-dimensional precision dimensional inspection

- Precision dimensions of single dimensions such as inner diameter, outer diameter, and height of the ring gauge master part

Length reference calibration

- Calibration of master parts, gauge blocks, and other length-based reference values

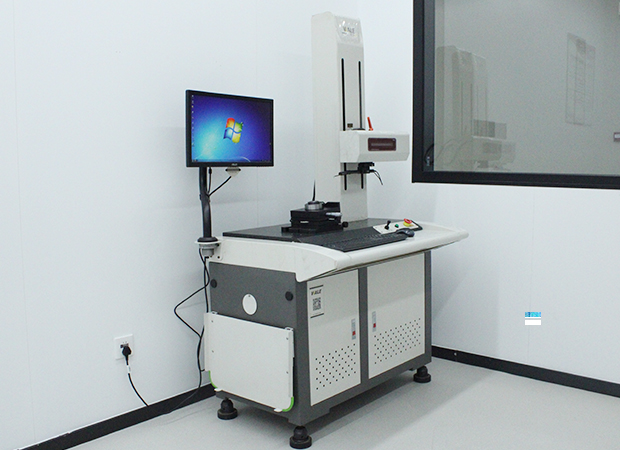

Imaging device

Two-dimensional plane size inspection

- The two-dimensional dimensions of bearing components, such as the end face groove width, chamfer angle, and seal groove contour

Surface micro-defect detection

- Assist in observing micro-processing defects such as scratches and chipped edges on the surface of components

Planar geometric tolerance inspection

- In-plane geometric tolerances such as parallelism and positional accuracy

instrument calibration

Calibration service

- Calibration services can be provided for items such as gauge blocks, optical instruments, precision measuring instruments and equipment, general-purpose measuring tools, various gauges, and inspection tools for product inspection

Mechanical property analysis

Testing and analysis of material mechanical properties to evaluate the performance of materials under various working conditions

Microcomputer-controlled high and low temperature electronic universal testing machine

High and low temperature environmental mechanical property testing: Simulate working conditions ranging from -40℃ to 300℃ (or customized range), and measure the tensile strength, yield strength, and elongation of bearing materials (such as bearing steel, stainless steel) and components (rolling elements, cages)

Testing and analysis of material mechanical properties to evaluate the performance of materials under various working conditions

Rolling element crushing test: Apply axial pressure to rolling elements such as steel balls and rollers, measure the crushing load, and evaluate the overload resistance of the rolling elements.

Material testing service

Comprehensive material analysis and testing services, providing comprehensive testing from composition to performance

Sample preparation and preparation (basic support)

1. Metallographic cutting machine

Core testing content: Precisely cutting bearing material samples (such as rings and small rolling elements) to prepare sample blanks suitable for subsequent analysis

2. Inlay machine

Core testing content: Mount and shape the bearing sample to form a regular sample block for subsequent grinding, polishing, and testing

3. Grinding and Polishing Machine

Core testing content: Grind (coarse grinding → fine grinding) and polish the embedded bearing samples to remove cutting marks, achieving a flat and glossy sample surface that meets the clarity requirements for microscopic observation

Material composition analysis

Spectrometer

Core testing content: Testing the content of key elements (such as C, Cr, Si, Mn, Mo, etc.) in bearing metal materials (such as GCr15 bearing steel, stainless steel)

Microstructure analysis

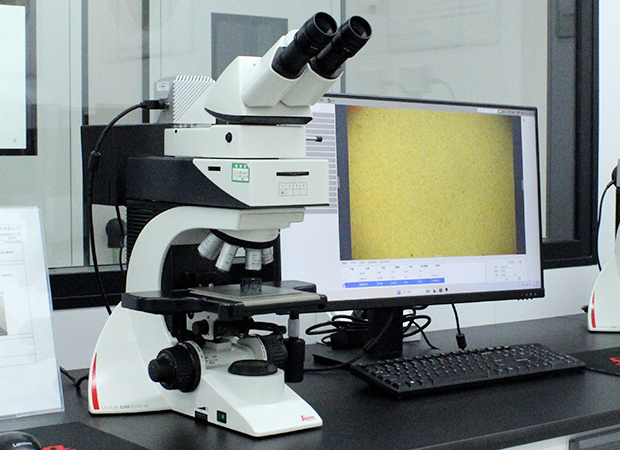

1. Metallographic microscope

Core testing content: Observing the internal microstructure of bearing metal samples, detecting internal inclusions and microcracks

2. Stereo microscope

Core inspection content: Observe the surface/near-surface defects (scratches, chipping, corrosion marks) of bearing materials under low magnification, or inspect the microstructure of non-metallic components (plastic cages) for injection molding bubbles and stress cracks

hardness testing

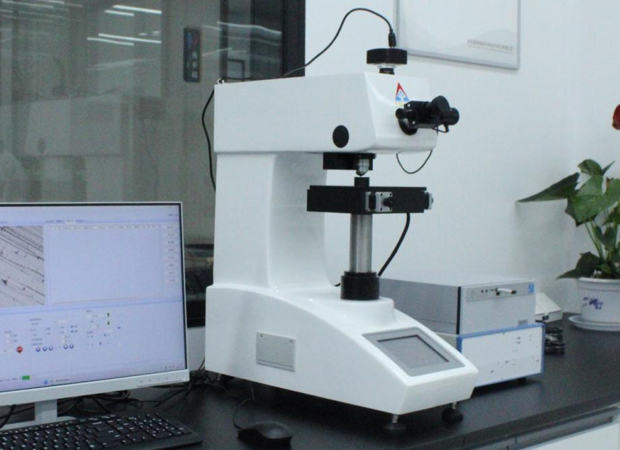

1. Vickers hardness tester

Core testing content: Apply a small load, measure the diagonal length of the indentation on the surface of the bearing material, and calculate the Vickers hardness value; suitable for thin materials, coatings, and small areas (such as the coating on the bearing surface and thin cages)

2. Rockwell hardness tester

Core testing content: Apply load, measure the indentation depth on the bearing material surface, calculate the Rockwell hardness value; suitable for medium and high hardness materials (such as quenched bearing rings, rolling elements)

3. Brinell hardness tester

Core testing content: Apply a large load, use a hard alloy ball to press an indentation on the surface of the bearing material, measure the indentation diameter, and calculate the Brinell hardness value; suitable for soft/unquenched materials (such as bearing blanks, annealed bearing steel)

4. Shore hardness tester

Core testing content: Measure the Shore hardness of non-metallic components of bearings (such as rubber seals, plastic cages), and evaluate the elasticity and hardness characteristics of the materials

Material testing services - Testing machine special project

Professional testing machine inspection services, simulating various working conditions to test material performance

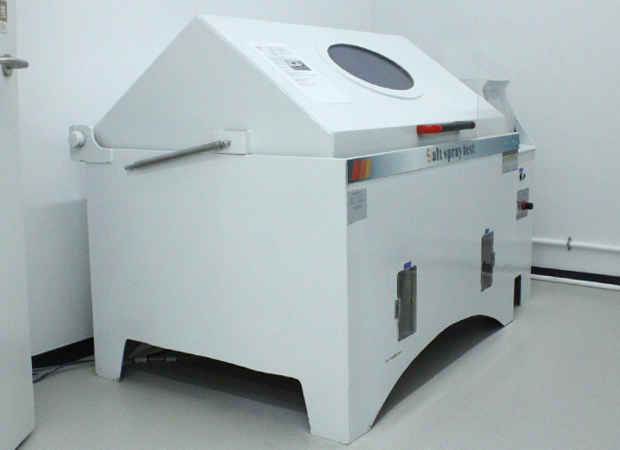

Intelligent salt spray testing machine

Corrosive test

Simulate a corrosive environment by subjecting bearings (such as stainless steel bearings and carbon steel bearings with anti-rust coatings) to salt spray for 24 to 1000 hours, observe the time and area of rusting on the surfaces of the rings and rolling elements, and evaluate the adhesion and damage of the anti-rust coating.

Life-cycle strengthening testing machine

Bearing life test

Simulate the harsh operating conditions of high speed and high load in the actual operation of bearings, record the cumulative operating time of continuously running bearings, monitor changes in vibration values, temperature, and noise in real time, and determine the fatigue life.

Outer spherical bearing splash resistance testing machine

Sealing integrity test

For outer spherical bearings, simulate splashing environments involving different types of liquids such as mud, coolant, and sewage. Continuously splash the liquid and operate the bearings. After the test, inspect the amount of water/oil contamination inside the bearings to evaluate the protective effectiveness of the sealing structure (such as sealing rings and dust covers).

轴承泥浆试验机

泥浆环境耐受性测试

模拟重型机械、工程车辆在泥浆环境中的工作条件,测试轴承在泥浆介质中的密封性能、耐磨性和使用寿命。

测试标准

- 泥浆浓度:可调

- 测试温度:无

- 转速范围:最大2000r/pm

- 测试周期:根据客户要求订制

轴承粉尘试验机

粉尘环境密封性测试

模拟矿山、水泥厂、面粉加工等粉尘环境,测试轴承防尘密封性能,评估在细微粉尘颗粒环境中的使用寿命和可靠性。

测试特点

- 精确控制:可设定总试验时间、转速、支持五段循环程序控制

- 实时监控:24小时不间断记录数据

- 转速:最大460r/min

Bearing inspection service

Professional bearing testing and analysis to ensure that bearing accuracy and performance meet standard requirements

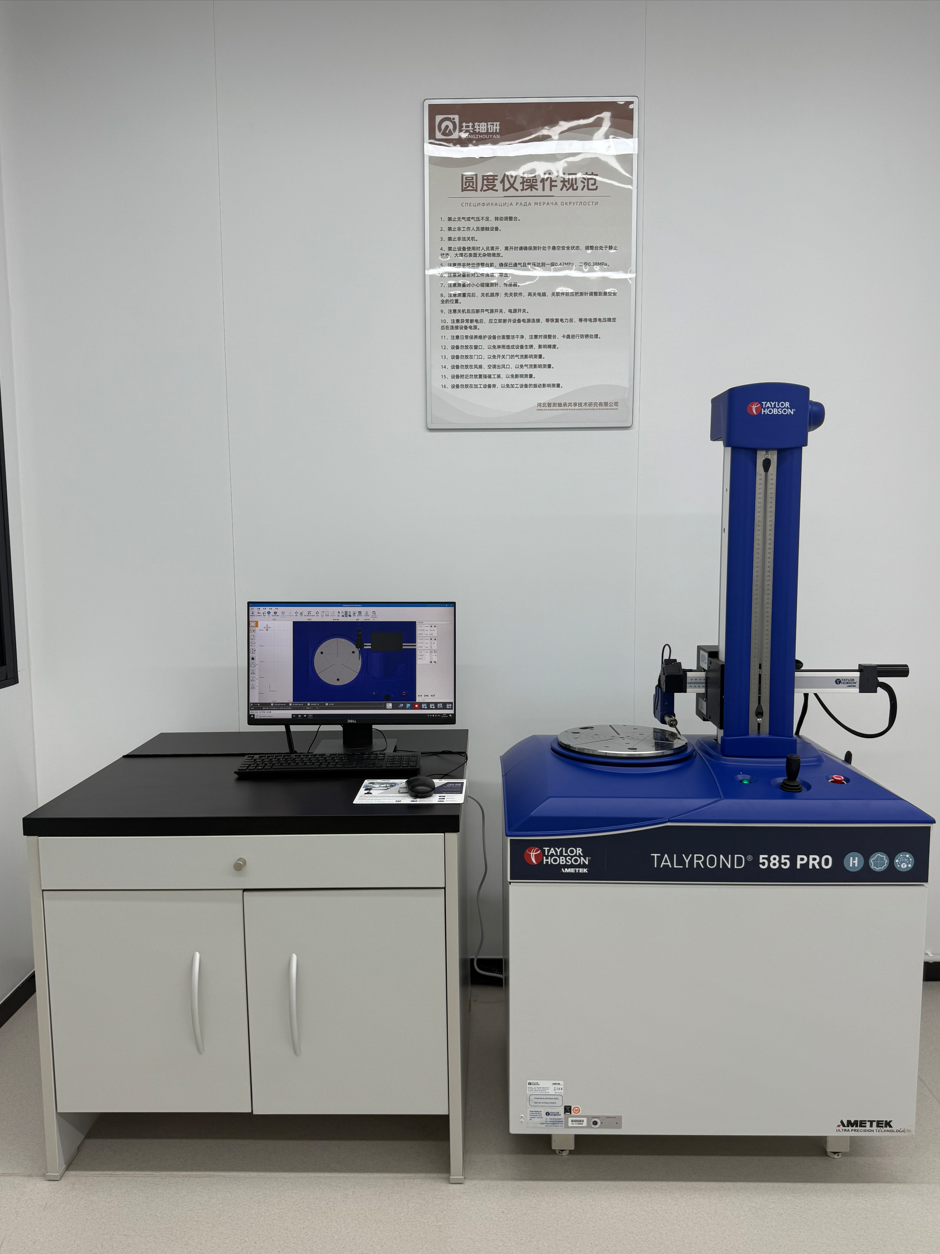

Roundness gauge inspection

Roundness error of circular components of bearings

Measure the roundness deviation of circular surfaces such as the inner and outer raceways of bearing rings, steel balls/rollers, etc

Waviness and eccentricity detection

Assist in measuring the waviness (periodic shape deviation) of the raceway surface and the eccentricity (center offset between the inner and outer circles) of the bearing ring

Specific section analysis

Select key positions such as the end face of the bearing ring and the raceway section, and individually inspect the roundness accuracy of these sections

Cylindricity instrument inspection

Overall error of bearing cylindrical surface

Measure the cylindricity deviation of the inner and outer cylindrical surfaces of the bearing ring, and evaluate the overall shape accuracy of the cylindrical surface

Correlation error detection

Simultaneous measurement of roundness, coaxiality, and straightness of cylindrical surfaces

Bearing roller inspection

Perform precise measurement of the generatrix cylindricity of cylindrical rollers and tapered rollers to ensure the fit between the rolling elements and the raceway

Profilometer inspection

Two-dimensional contour shape of bearing

Detect shape deviations of two-dimensional contours such as bearing seal grooves, chamfers, raceways, and ribs (e.g., groove fillet, chamfer angle, and raceway curvature radius)

Outline dimension accuracy

Measure key dimensions of the contour (such as seal groove width, groove depth, chamfer length, and channel position deviation) to verify compliance with the design drawings

各类表台检测

Quick dimensional screening of bearings

Use a dial gauge/micrometer to measure precise dimensions such as the inner and outer diameters, wall thickness, and end face thickness of bearings, enabling rapid qualification assessment of batches of components

Bounce detection

Use a lever gauge/dial gauge to detect the end face runout and radial runout of the bearing ring

Assistive calibration

As a benchmark measuring tool, it assists in calibrating the zero position or local measurement accuracy of equipment such as three-coordinate measuring machines and length measuring instruments

Radial clearance measuring instrument for radial ball bearings

Static radial clearance detection

Fix the radial ball bearing onto the fixture, apply a specified static load in the radial direction, causing relative radial displacement between the inner and outer rings of the bearing. The displacement value read is the static radial clearance (original clearance). Verify whether it conforms to the clearance grade specified in the standard for the corresponding bearing model

Bidirectional displacement monitoring

Apply loads in both radial positive and negative directions, measure the bidirectional displacement difference to eliminate the unilateral clearance deviation caused by bearing installation skew, and ensure the comprehensiveness of the clearance data

Multi-size bearing compatibility testing

It is compatible with radial ball bearings of different inner diameters, and by changing the fixture, it can achieve universal measurement of radial clearance for small and medium-sized radial ball bearings

Clearance conformity assessment

Compare the measured value with the clearance range specified in the design drawings or standards to determine whether the bearing radial clearance is qualified

ancillary services

专业的辅助检测服务,确保检测过程的完整性与准确性

Sample cleaning

Professional cleaning and treatment

A series of procedural operations are carried out on the bearings, including rust and oil removal as well as rust prevention treatment, to ensure the cleanliness and accuracy of the test samples.

Our cleaning services include:

- Ultrasonic cleaning removes surface oil stains and impurities

- Chemical rust removal treatment protects the substrate from damage

- Professional anti-rust treatment prevents samples from oxidizing during the testing process

- Professional anti-rust treatment prevents samples from oxidizing during the testing process

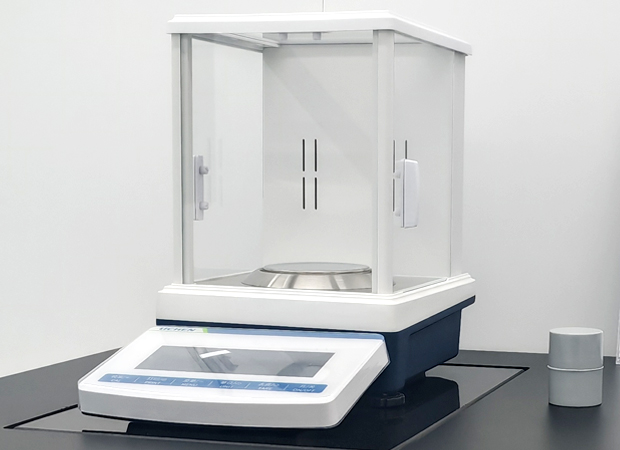

Trace measurement

High-precision mass measurement

Use a high-precision balance to measure the mass of tiny parts, ensuring the accuracy and reliability of the measurement results.

Our micro-measurement services include:

- Use an analytical balance with a precision of one ten-thousandth for mass measurement

- Accurate weighing of micro-bearing components and rolling elements

- Assistance in material density calculation and composition analysis

- Measurement environment and process that meet international standards

冀ICP备2025126555号-2

冀ICP备2025126555号-2